Additional Capabilities

F-16 Fighting Falcon

Customer: Lockheed Martin Aeronautics Company

The F-16 Fighting Falcon is a compact multi-role fighter aircraft. It is highly maneuverable and has proven itself in air-to-air combat and air-to-surface attack. It provides a relatively low-cost, high performance weapon system for the United States Air Force and many other allied nations. In an air combat role, the F-16’s maneuverability and combat radius exceed that of all potential threat fighter aircraft. It can locate targets in all weather conditions and detect low flying aircraft in radar ground clutter. In an air-to-surface role, the F-16 can fly more than 500 miles, deliver its weapons with superior accuracy, defend itself against enemy aircraft, and return to its starting point. An all-weather capability allows it to accurately deliver ordinance during non-visual bombing conditions.

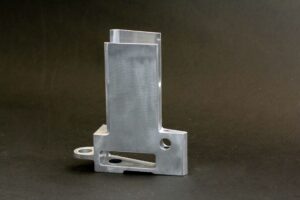

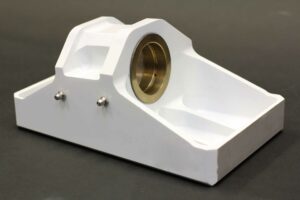

Seanair has helped to continue this valuable program with the manufacture of structural parts and weapon delivery components. Some examples of these parts can be seen in the gallery.

F-35 Joint Strike Fighter

Customer: Lockheed Martin Aeronautics Company

The F-35 Lightening II was conceived in the mid 1990’s as the pinnacle of more than 50 years of fighter development technology. Designed to dominate the skies, the F-35 combines the 5th Generation characteristics of radar evading stealth, supersonic speed and extreme agility with the most powerful and comprehensive integrated sensor package of any fighter aircraft in history. The F-35’s built-in sustainment establishes new levels of operational readiness. Aircraft share common parts, support equipment and technical data, yielding greater reliability and long-term cost savings. In three variants – conventional, short takeoff / vertical landing, and carrier launched – the F-35 represents the versatility that would be required by any military force defending it’s land, sea or sky.

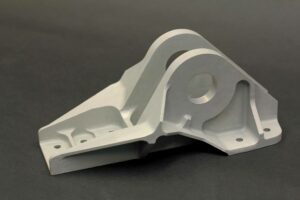

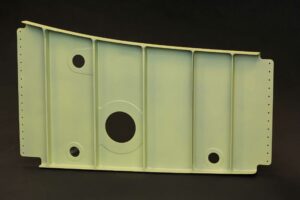

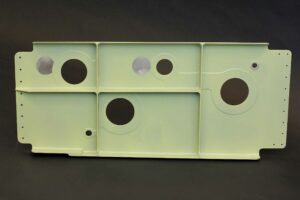

Seanair lends it’s high technology machining expertise to this program in the form of structural parts, wing structure parts, and removable panels. Some examples of these parts can be seen in the gallery.

Sh60 Seahawk

Customer: Sikorsky Aircraft

The UH-60 Black Hawk is a utility tactical transport helicopter that serves as the backbone for the U.S. Army’s Air Cavalry. The versatile Black Hawk has enhanced the overall mobility of the Army, due to dramatic improvements in troop capacity and cargo lift capability. An entire 11 person, fully equipped infantry squad can be lifted in a single Black Hawk, transported faster than in predecessor systems, in most weather conditions. The Black Hawk can reposition a 105mm Howitizer, its crew of six, and lift up to 30 rounds of ammunition in a single lift. The basic airframe has been customized for different roles, and is used by the U.S. Navy in a submarine search role, and by the U.S. Air Force in a search and rescue role.

Seanair has been a part of this program since its development, providing airframe components and critical flight control parts. Some examples of these parts can be seen in the gallery.

V22 Osprey

Customer: Bell Helicopter

The V-22 Osprey is the first aircraft designed from the ground up to meet the needs of all the branches of the U.S. armed services. The tiltrotor aircraft takes off and lands like a helicopter. Once airborne, its engine nacelles can be rotated to convert the aircraft to a turboprop airplane capable of high-speed, high altitude flight. In the airplane configuration, the Osprey can travel twice as fast as a helicopter with a much longer range, which results in greater mission versatility than a helicopter. The V-22 can carry up to 24 mission-ready combat troops. It has 20,000 pound internal capacity or 15,000 pound external capacity using it’s medium lift and vertical takeoff and landing capabilities. Because it’s rotors and wings fold, it can be stored aboard an aircraft carrier or assault ship. Air-to-air refueling gives the Osprey the ability to self deploy.

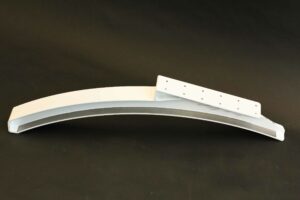

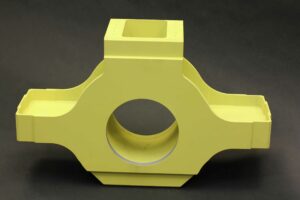

Seanair has been a part of this unique program since it’s inception. We manufacture all of the machined fittings found inside the composite flaperons, along with the hard-point attach hinges. Some examples of these parts can be seen in the gallery.